Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

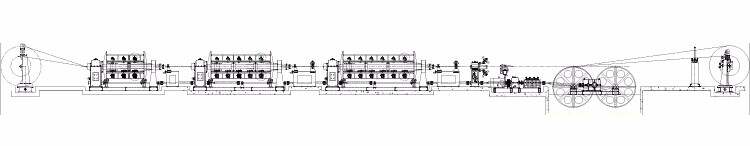

500/48+48 Steel wire armor rigid framed stranding machine

The 500/48+48 Steel Wire Armor Rigid Framed Stranding Machine is a robust, high-speed solution for stranding copper, aluminum, and ACSR conductors, including irregular conductor shapes. With integrated tape wrapping, pneumatic systems, and advanced control features, this machine ensures high efficiency, consistent tension, and superior conductor forming. It is ideal for large cross-section wire and cable production, offering enhanced safety, reliability, and productivity for demanding industrial applications.

Product Features

Wide Stranding and Wrapping Capability

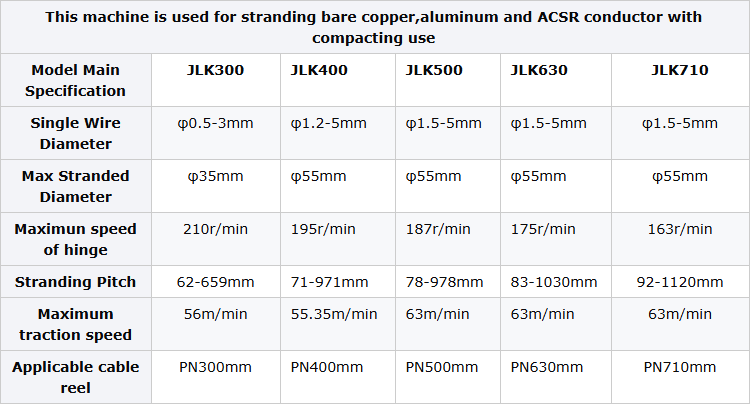

Handles single wire diameters from φ1.5–5mm and stranded diameters up to φ55mm, with built-in tape wrapping functionality for shielding and reinforcement.

Automatic Tension Adjustment System

Maintains stable tension throughout the process, whether the bobbin is full or nearly empty, ensuring consistent strand quality.

Flexible Motor Configuration with High-Speed Output

Supports both single and split motor drives with a maximum hinge speed of 187r/min and pitch range of 78–978mm for versatile production control.

Efficient Bobbin and Wire Forming Design

Includes upper/lower integrated bobbins with pneumatic clamping, a sector-shaped compacting mold, and a wire merging mold for smooth conductor shaping.

Safety-Enhanced and User-Friendly Operation

Features pneumatic brakes, electric safety fences on each carriage, and side-loading systems for easy and secure operation and maintenance.

Technical Specifications

Product Advantages

Ideal for Steel Wire Armoring and Shielding

Built-in tape wrapping supports production of armored cables and shielding layers, expanding production capabilities.

Precision Lubrication System

Individual motor-driven gear pump ensures optimal gearbox lubrication, improving machine lifespan and operational stability.

Reduces Downtime and Labor Costs

Pneumatic clamping and side-loading devices enable fast bobbin changes, boosting operational efficiency and lowering manual intervention.

Stable and Uniform Output

The automatic tension control system guarantees consistent cable quality even during high-speed or long production runs.

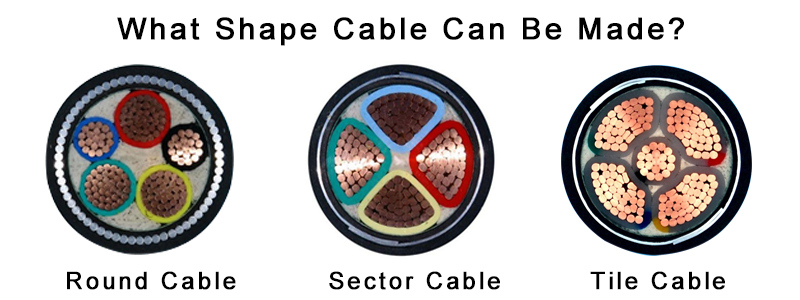

Supports a Variety of Conductor Shapes

Efficiently handles circular, fan-shaped, and tile-shaped conductors, making it suitable for a wide range of cable manufacturing needs.

Hanging Device:

What Shape Cable Can Be Made?