Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

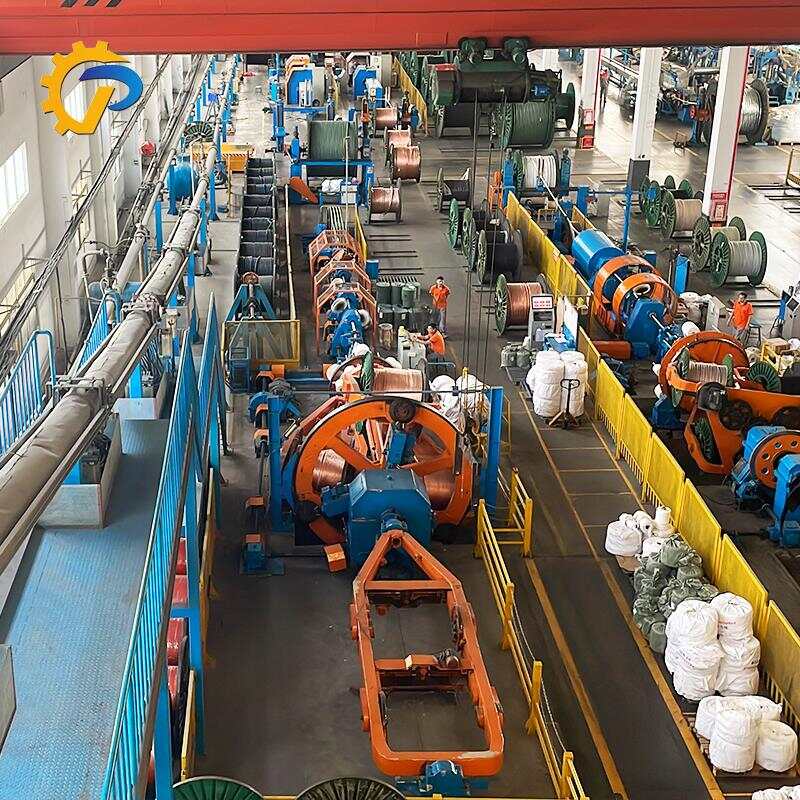

Cabie Stranding Machine

(73)1600/2+3 cable laying up machine

The 1600/2+3 cable laying up machine is designed for assembling 5-core power cables ranging from 95mm² to 500mm². With its advanced performance, practical structure, and easy maintenance, this equipment is the ideal choice for small and medium-sized cable manufacturing enterprises seeking efficiency and reliability.

1600/1+1+3 cable laying up machine

The 1600/1+1+3 cable laying up machine is a high-performance equipment designed to assemble multi-core cables efficiently and precisely. Suitable for power cables, control cables, and armored cables, it features a 1600 mm cradle and a 1+1+3 configuration for versatile production. With robust construction and user-friendly operation, it’s an ideal choice for small and medium-sized cable manufacturers looking to enhance output quality and production flexibility.

1400/1+1+3 cable laying up machine

The 1400/1+1+3 cable laying up machine is engineered for producing multi-core cables ranging from 50mm² to 300mm². Designed for efficiency, precision, and ease of use, this machine features advanced performance, flexible reverse/non-reverse torsion control, and ergonomic operation. Its compact structure and robust design make it the ideal solution for small and medium-sized cable manufacturing enterprises seeking dependable, high-output machinery.

1400/2+3 cable laying up machine

The 1400/2+3 cable laying up machine is a high-efficiency production line designed for manufacturing multi-core PVC and XLPE insulated cables with integrated taping and armoring functions. Made from high-quality iron and steel, this fully automatic machine delivers stable performance and is ideal for small to medium-sized cable manufacturers aiming to boost productivity and output quality.

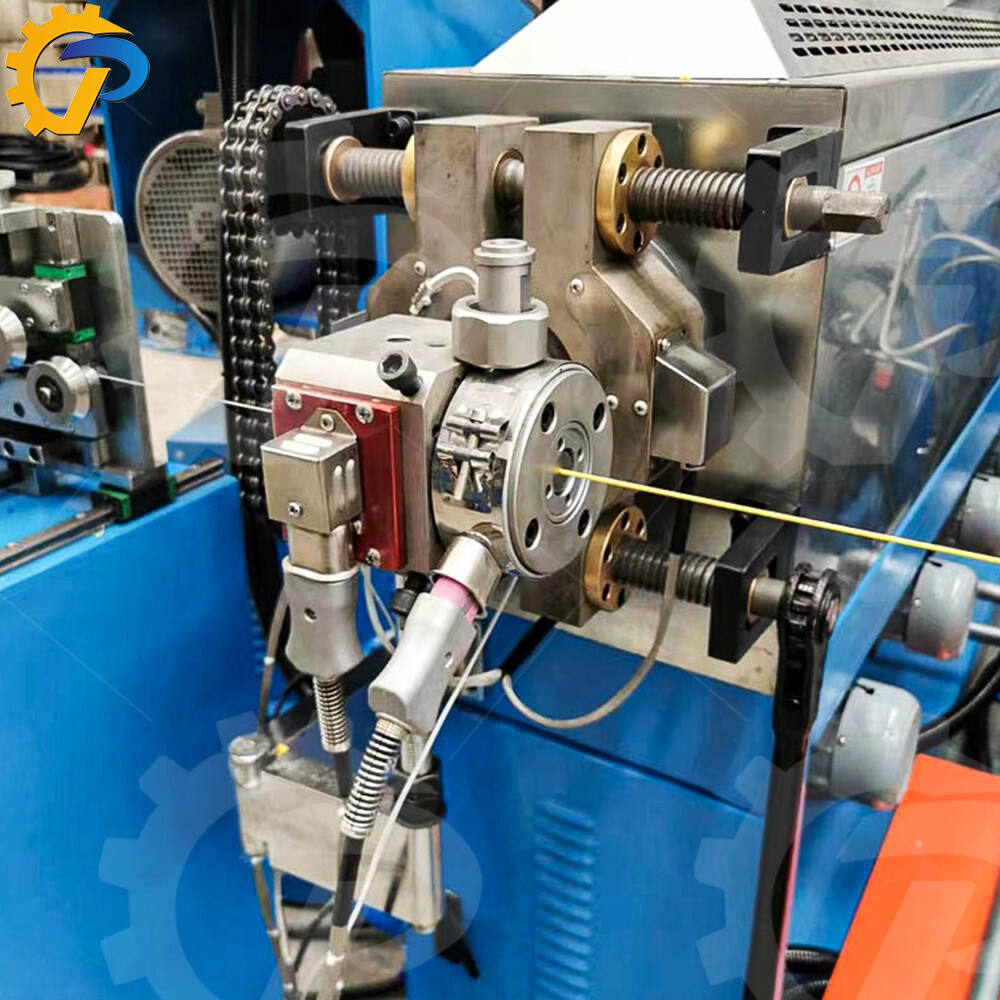

Cable Extrusion Machine

(18)50 cable extrusion machine

The 50 Cable Extrusion Machine is designed for high-precision extrusion of insulation and sheath layers for wires and cables, including USB wires. Supporting materials like PVC, XLPE, PE, and HFFR, this machine ensures consistent quality with customizable extruder sizes (SJ30-SJ150) and layer configurations (single, double, or triple-layer co-extrusion). Ideal for manufacturers seeking durable, flame-retardant, and high-performance cable production, this machine enhances efficiency and output reliability.

50+35 cable extrusion machine

The 50+35 cable extrusion machine is an advanced solution for producing high-quality insulated and sheathed cables with single or double-layer extrusion. It supports various materials such as PVC, XLPE, and flame-retardant polyolefins, making it ideal for industrial cable manufacturing. With PLC control and touch screen operation, this equipment delivers high-speed, automated production with excellent precision and efficiency.

60 cable extrusion machine

The 60 cable extrusion machine is a high-performance solution designed for the efficient extrusion of insulation and sheath layers on wires and cables. Engineered with PLC and touch screen control, it ensures smooth operation, minimal maintenance, and high-speed production. This machine is compatible with a wide range of materials, including PVC, XLPE, PE, and HFFR, making it ideal for modern cable manufacturing facilities.

60+35 cable extrusion machine

The 60+35 Cable Extrusion Machine is a high-performance, dual-layer extrusion system designed for precision and efficiency in wire and cable production. Combining a 60mm primary extruder with a 35mm secondary extruder, this machine ensures uniform material distribution, high output, and superior insulation/sheath quality. Ideal for PVC, XLPE, and flame-retardant polyolefin materials, it is perfect for large-scale manufacturing of durable, high-grade cables.

Wire Drawing Machine

(4)400-13D aluminium wire Rod Breakdown machine

The 400-13D Aluminium Wire Rod Breakdown Machine is a high-performance wire drawing solution designed to process aluminum rods into fine wire with precision and efficiency. Integrating advanced domestic and international technology, it features a seven-die drawing system, automated tension control, and touchscreen interface, ensuring high-speed, low-noise, and energy-efficient production. Ideal for manufacturers seeking consistent output, operational safety, and simplified maintenance in aluminum wire processing.

400-13D copper Rod Breakdown machine

The 400-13D Copper Rod Breakdown Machine is a high-performance wire drawing solution engineered for efficient and precise processing of copper rods into fine wires. Designed with a horizontal tandem layout, this machine offers energy-saving operation, low noise, and intelligent control through a touchscreen interface. It is ideal for manufacturers seeking automation, productivity, and consistent wire quality for cable and conductor production.

17D Intermediate wire drawing machine

The 17D Intermediate Wire Drawing Machine is designed for precision drawing of copper wires from φ2.6–3.0mm down to φ0.4–1.2mm, with integrated annealing and tension control. Built for high-performance and continuous production, it features 21 drawing dies, advanced DC annealing system, and robust construction for stable, high-speed output up to 1800m/min. It is ideal for medium-gauge copper wire processing in cable and electrical manufacturing.

22D fine wire drawing machine

The 22D fine wire drawing machine with online annealer is designed for high-speed drawing and annealing of copper wire, reducing wire diameters from 0.8–1.6mm to 0.2–0.6mm. Engineered for precision and efficiency, this robust machine features 22 drawing dies, three-section annealing, and advanced inverter control, making it ideal for fine copper wire production in electrical, electronics, and cable manufacturing industries.