Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

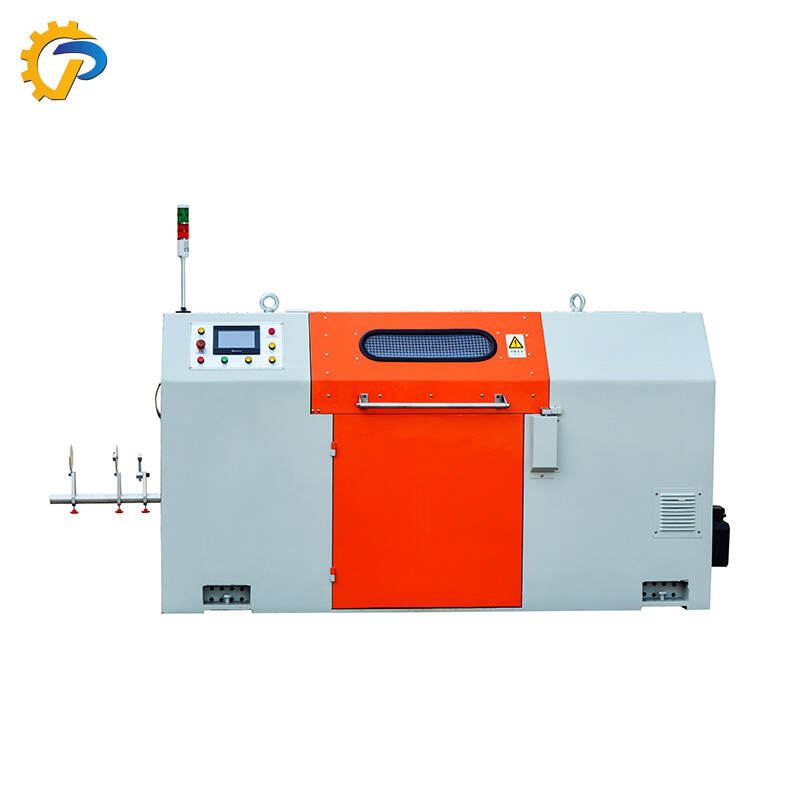

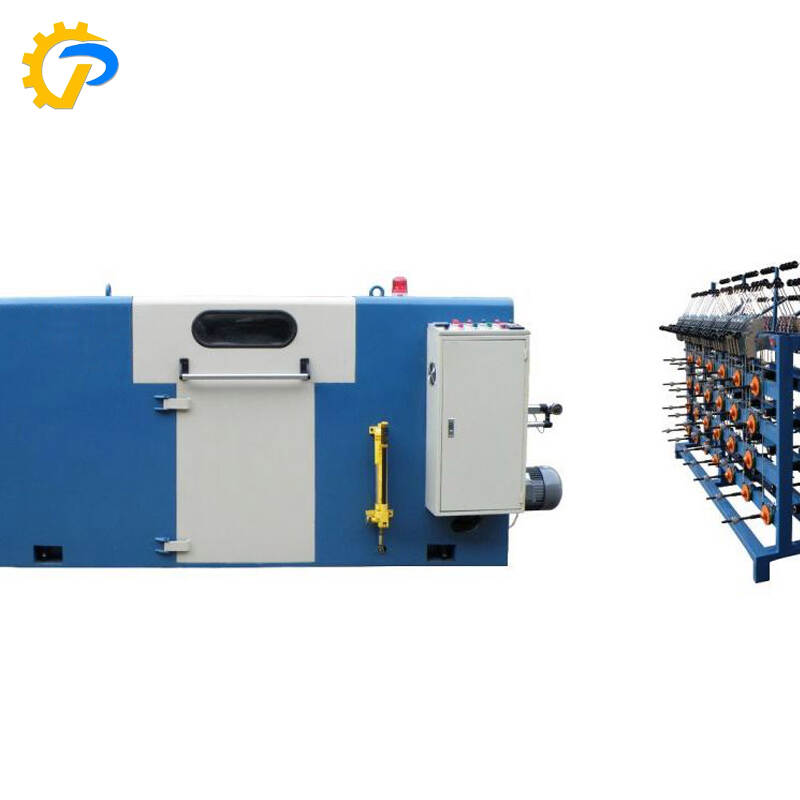

500 bunching machine

The 500 Bunching Machine is a high-performance cable twisting solution designed for precision, safety, and operational efficiency. With a dual-speed transmission system, advanced control interface, and robust construction, this machine is ideal for high-quality wire processing in industrial cable production. Its intelligent features and safety-focused design make it a reliable choice for modern manufacturing lines.

Product Features

Dual-Speed Transmission for Flexible Operation

Equipped with a two-stage speed adjustment system, the machine allows smooth and flexible control over production speeds, ensuring compatibility with various cable types and production requirements.

Advanced Safety with Sliding Door and Electromagnetic Locking

Designed with a sliding door structure and integrated with safety protection and electromagnetic interlocking, this machine offers maximum operator safety during use and maintenance.

Precision Machining for Structural Stability

The frame is made from Q235 steel, formed by welded iron plates, stress-relieved through annealing, and precision-machined to guarantee structural accuracy and long-term durability.

High-Strength Main Shaft with Enhanced Wear Resistance

The main shaft is manufactured from 40Cr alloy steel, quenched and tempered to reach HB250 hardness. Surface treatment on the bearing seat improves wear resistance and extends service life.

Intelligent HMI Control System with Data Sampling

Features a user-friendly human-machine interface (HMI) that allows operators to monitor and set key parameters such as production time, wire diameter, and real-time tension—enhancing efficiency and quality control.

Technical Specifications

Product Advantages

Stable and Consistent Tension Control

Utilizes a magnetic powder clutch to automatically regulate wire tension from empty to full spool, maintaining consistent tension throughout the operation.

Reliable Lifting System

The spool lifting mechanism uses an electro-hydraulic system for smooth, stable movement, reducing mechanical stress and boosting reliability.

Energy-Efficient Ventilation and Lighting

Equipped with a touch-controlled exhaust fan and lighting system that can be turned off when not in use, promoting energy savings.

Clear Fault Indications for Quick Maintenance

Displays fault conditions such as wire breaks via a pull-down red text alert, allowing operators to quickly identify and resolve issues.

Automatic Shutdown and Safety Alerts

Supports full-spool auto-stop, wire break auto-braking, and safety door or top cover malfunction alarms, ensuring production safety and reducing downtime.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost