Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

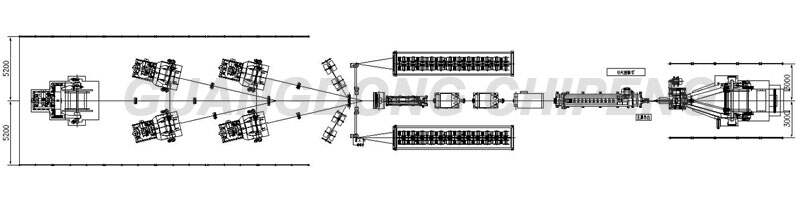

3150/4+1 drum twister machine

The 3150/4+1 Drum Twister Machine is a high-performance cable laying-up machine designed for large-section and long-length power cables. It is also suitable for steel/copper wire armoring, shielding, and other cable manufacturing processes. With advanced PLC control, AC/DC motor drives, and a user-friendly touchscreen interface, this machine ensures precision, efficiency, and reliability in cable production.

Key Features

1. Advanced PLC Control System

Precision Operation: Automatically regulates motor synchronization, speed, and tension.

Real-Time Monitoring: Displays and stores process parameters for optimal performance.

Fault Diagnosis: Detects and displays faults on the touchscreen for quick maintenance.

2. High-Efficiency Motor Configuration

AC Variable Frequency Motors: Used for pay-off, twisting, wrapping, and traction (speed controlled by inverters).

DC Motor for Take-Up: Equipped with Parker590 DC drive, ensuring stable tension (adjustable via touchscreen).

3. Flexible Process Control

Adjustable Cable Pitch: Set, modify, and display on the touchscreen.

Directional Control: Supports left/right wiring, jogging, and fast-speed movement.

Back Twist Rate: Freely adjustable from 0-100% for optimal cable quality.

4. Robust Mechanical Design

Drum Twisting Structure: Ensures high productivity, easy loading/unloading, and low noise.

High-Strength Components: Precision-engineered for smooth rotation and durability.

5. Safety & Protection Systems

Multiple Protections:

Cable rack fork horizontal protection

Speed control fault alarm

Hydraulic lift reset protection

Over-travel limit switch

Air pressure undervoltage protection

Broken tape detection

Technical Specifications

|

Model |

3150/4+1 |

|

Max Wire Diameter |

Φ25~Φ120mm |

|

Max Pay-Off Speed |

33 r/min |

|

Max Line Speed |

50 m/min |

|

Caterpillar Max Load |

4000 kg |

|

Back Twist Rate |

0-100% adjustable |

|

Take-Up Motor |

DC motor (Parker590 drive) |

|

Control System |

PLC + Touchscreen HMI |

Main Components

1. Center Rotating Pay-Off

Fork-type cantilever design, driven by an independent motor.

Pneumatic tension control (adjustable during operation).

Shaft-less bobbin clamping for easy loading/unloading (crane-assisted).

Pneumatic brake & manual jog control.

2. Dual-Disc Non-Metallic Taping Head

Materials Supported: Polyester tape, non-woven fabric, glass cloth, copper tape, etc.

AC motor + inverter control, with left/right rotation.

Mechanical friction tension control for stable winding.

Auto-stop function when tape runs out.

3. Dual-Disc Steel Tape Armoring Head

Similar to non-metallic taping head but optimized for steel tape.

Pneumatic brake & tension feedback for consistent performance.

4. 6T Rotating Caterpillar

Max Load Capacity: 6000 kg

Max Line Speed: 50 m/min

Motor Power: 37 KW (AC variable frequency motor)

5. Rotating Take-Up

Fork-type support wheel, DC motor-driven (max tension: 250 kg).

Hydraulic lifting platform for easy bobbin handling.

AC traverse motor with automatic direction switching.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost