Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

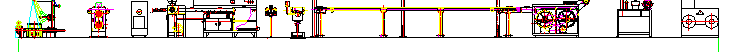

Chipeng 90+40 High Precision PLC Control Rubber Wire Extrusion Production Line

This machine is suitable for covering the sheath layer of wires and cables by extruding CPE (chlorinated polyethylene) thermoplastic cable material through the hot extrusion method. This machine has the advantages of high temperature control accuracy, stable wire output performance, energy saving and stability, as well as a high degree of automation.

Product Features

一、Product parameters

1.Outgoing speed: Max 150 meters/minute (depending on the amount of adhesive used for the wire)

2.Max glue output: 250kgs/hour (calculated with the machine head on, depending on the mobility of the glue material)

3.Electrical capacity: 400V 3-phase 4-wire 88KW 3P × 100A

4.Center height: 1000mm

5.Water: 3m3/Hr (reusable, replaced every 6 months)

6.Air pressure: 0.4Mpa 15m3Hr

7.Environmental humidity: not exceeding 95%

8.Attention: Once the electrical appliance is found to be damp, it must be dried before starting up.

二、Main electrical brands

1.Host motor: Yinmengdabeide

2.Inverter: sine wave

3.PLC: Siemens

4.Temperature control meter: RKC

三、Equipment list

1.630-800 single head shaftless magnetic powder tension pay off rack

2.600 Double Wheel Magnetic Powder Tension Frame

3. Organizer: Three group type

4.90/17 rubber extrusion host

5.40/16 Rubber extrusion payment machine

6.1.5-meter-high precision mobile sink

7. High precision caliper

8. Second section 12 meter U-shaped single-layer sink

9.1250 track tractor

10.800-1600 single head shaftless winding machine

11. PLC control main control box (with air conditioning)

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost