Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Cabie Stranding Machine

Cabie Stranding Machine

(73)JLY630/6+12+18 Planetary Stranding machine

The JLY630/6+12+18 Planetary Stranding Machine is a high-efficiency, heavy-duty stranding solution designed for control cables, power cables, and cross-linked cables. Featuring a star-shaped gear stranding structure and anti-twist technology, it ensures precise, uniform lay length and superior cable quality. With ground axis linkage, centrifugal break protection, and an advanced lubrication system, this machine delivers high-speed operation, reliability, and ease of maintenance, making it the ideal choice for small and medium-sized cable manufacturers.

JLY630/6+12 Planetary Stranding machine

The JLY630/6+12 Planetary Stranding Machine is engineered for high-efficiency stranding of bare copper, aluminum, ACSR conductors, and control cables such as KVV and XLPE power cables. With advanced mechanical structure and precise ground axis linkage, this machine offers excellent stranding quality and stable operation, making it a reliable choice for modern cable manufacturing facilities.

JLY630/1+6 Planetary Stranding machine

The JLY630/1+6 Planetary Stranding Machine is a versatile and advanced solution for cable manufacturing, designed to lay-up control cables, power cables, and cross-linked polyethylene cables with 61-wire conductors. With a cross-sectional area ranging from 1.5mm² to 6mm², this machine is ideal for small and medium-sized cable factories, offering precise, stable, and efficient production capabilities.

JLY630/24+24 Planetary Stranding machine

The JLY630/24+24 Planetary Stranding Machine is designed for high-precision stranding of control cables, power cables, and cross-linked polyethylene (XLPE) cables. Featuring advanced anti-twist technology, a robust cradle structure, and ground-axis linkage for stable pitch control, this machine ensures high-speed operation, durability, and superior cable quality—making it the ideal choice for small and medium-sized cable manufacturers.

JLY630/36+36 Planetary Stranding machine

The JLY630/36+36 Planetary Stranding Machine is designed for laying up control cables, power cables, and cross-linked cables with high precision and efficiency. Built for steel wire armoring applications, this advanced equipment offers robust structural performance, user-friendly operation, and high-speed functionality—making it the ideal solution for small to medium-sized cable manufacturing plants.

JLY630/48+48 Planetary Stranding machine

The JLY630/48+48 Planetary Stranding Machine is a high-performance solution designed for stranding steel wire armor and assembling control, power, and cross-linked cables. Engineered for precision, speed, and safety, this machine is ideal for small to medium-sized cable manufacturers seeking consistent quality and operational efficiency.

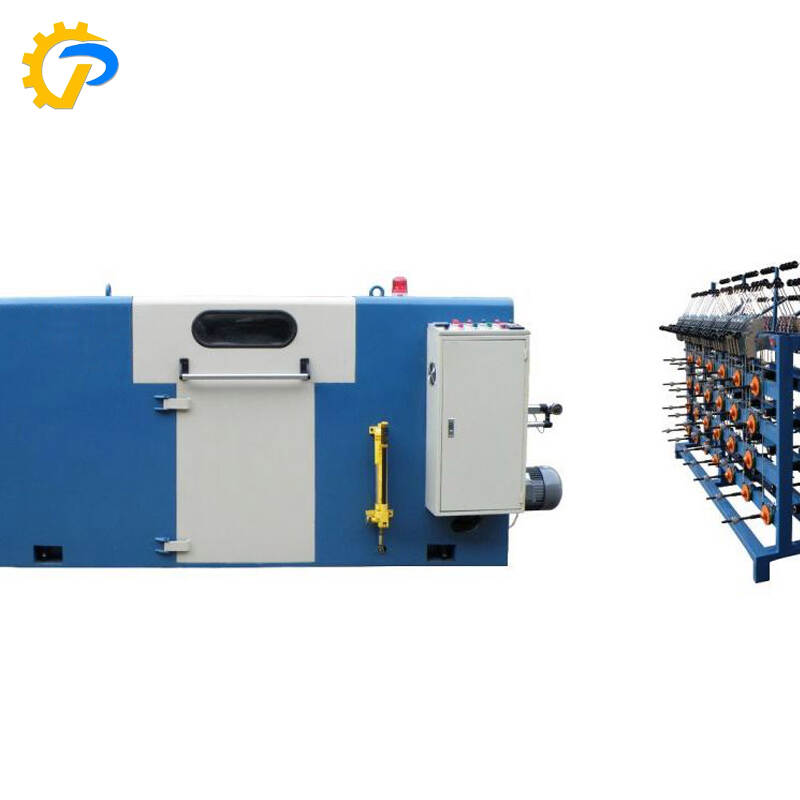

630 bunching machine

The 630 Bunching Machine is a high-efficiency solution engineered for precision cable twisting in modern wire and cable manufacturing lines. Built for durability, accuracy, and user safety, this machine integrates advanced control systems and tension management for consistent performance. Ideal for both small and large-scale production environments, it ensures optimal bunching of multiple wire strands with minimal downtime.

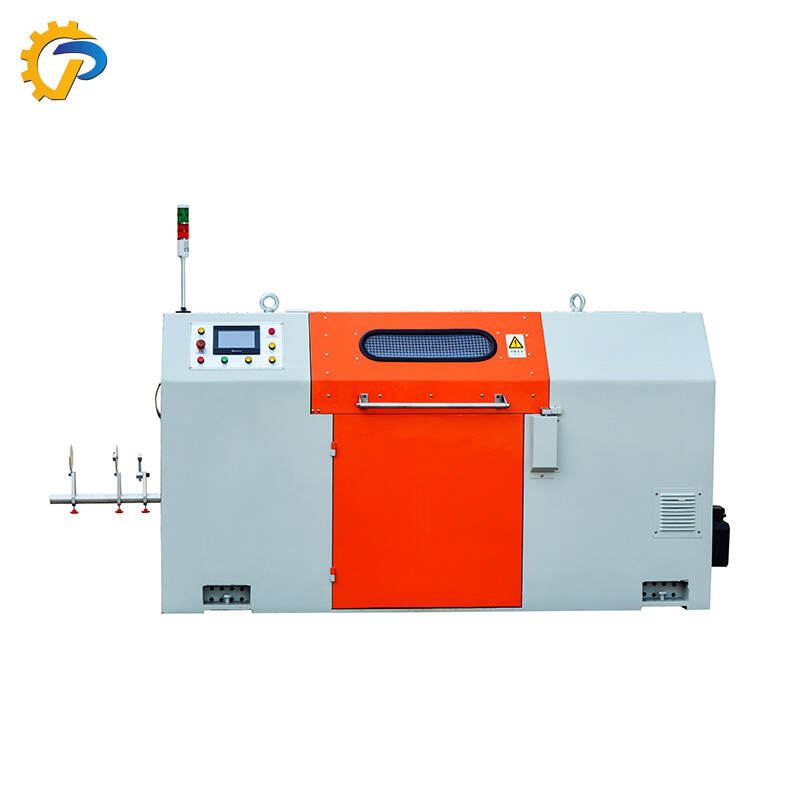

800 bunching machine

The 800 Bunching Machine is designed for efficient cable production, handling finished wire cross-sections from 2.5 mm² to 10 mm² and input wire diameters ranging from 0.23 mm to 1.05 mm. With advanced features like double gear change pitch and a user-friendly control system, this machine ensures high precision and reliability, making it an ideal choice for modern cable manufacturing facilities.

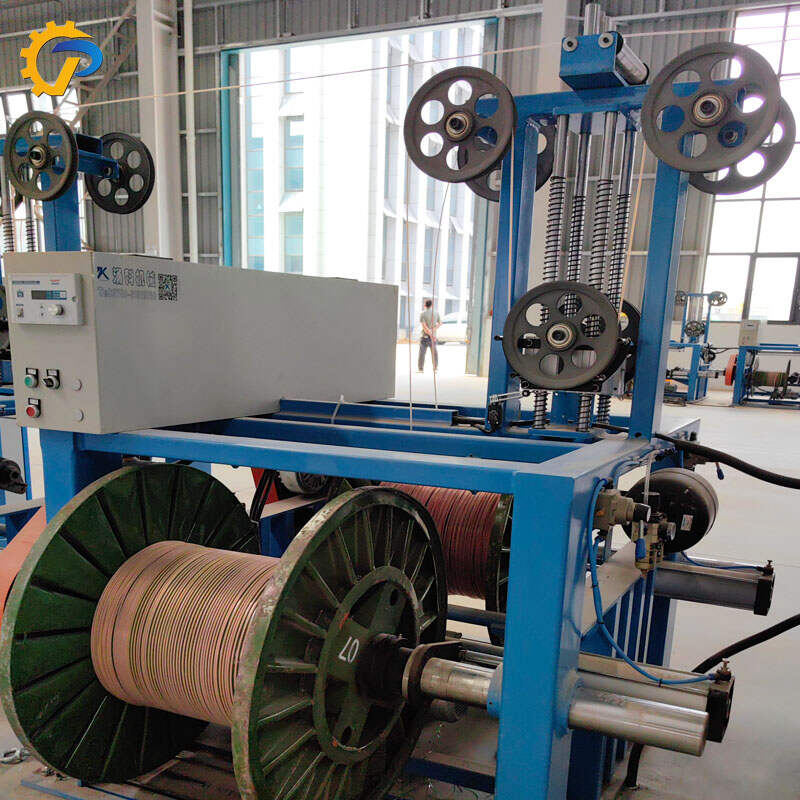

500 bunching machine

The 500 Bunching Machine is a high-performance cable twisting solution designed for precision, safety, and operational efficiency. With a dual-speed transmission system, advanced control interface, and robust construction, this machine is ideal for high-quality wire processing in industrial cable production. Its intelligent features and safety-focused design make it a reliable choice for modern manufacturing lines.

800 Cantilever single twisting machine

The 800 Cantilever Single Twisting Machine is an advanced stranding and bunching solution designed for high-speed precision cable manufacturing. Ideal for use in IT, aerospace, military, and medical applications, it supports the twisting of multiple wire types including bare copper, tinned, silver-coated, and enameled wires. Its cantilever structure and computer-controlled system ensure uniform tension, reduced wire bending, and consistently high-quality output while helping reduce production costs by up to 40%.

1000 Cantilever single twisting machine

The 1000 Cantilever Single Twisting Machine is a precision-engineered solution for twisting and synchronously winding insulated core wires, including LAN cables, power cables, and bare or coated wires. Designed using advanced domestic and international cabling technologies, it ensures stable pitch control, high-speed performance, and exceptional reliability—making it ideal for high-quality cable manufacturing across multiple industries.

1250 Cantilever single twisting machine

The 1250 Cantilever Single Twisting Machine is a high-precision stranding solution for round bare copper and insulated wires ranging from 3.0mm to 8.0mm in diameter. Designed for efficiency and flexibility, it supports center and side non-metallic tapping operations in one pass. With Siemens motors, servo-driven traverse, and programmable settings, this machine is built to meet the demands of modern cable manufacturing with high-speed output and reliable performance.