Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

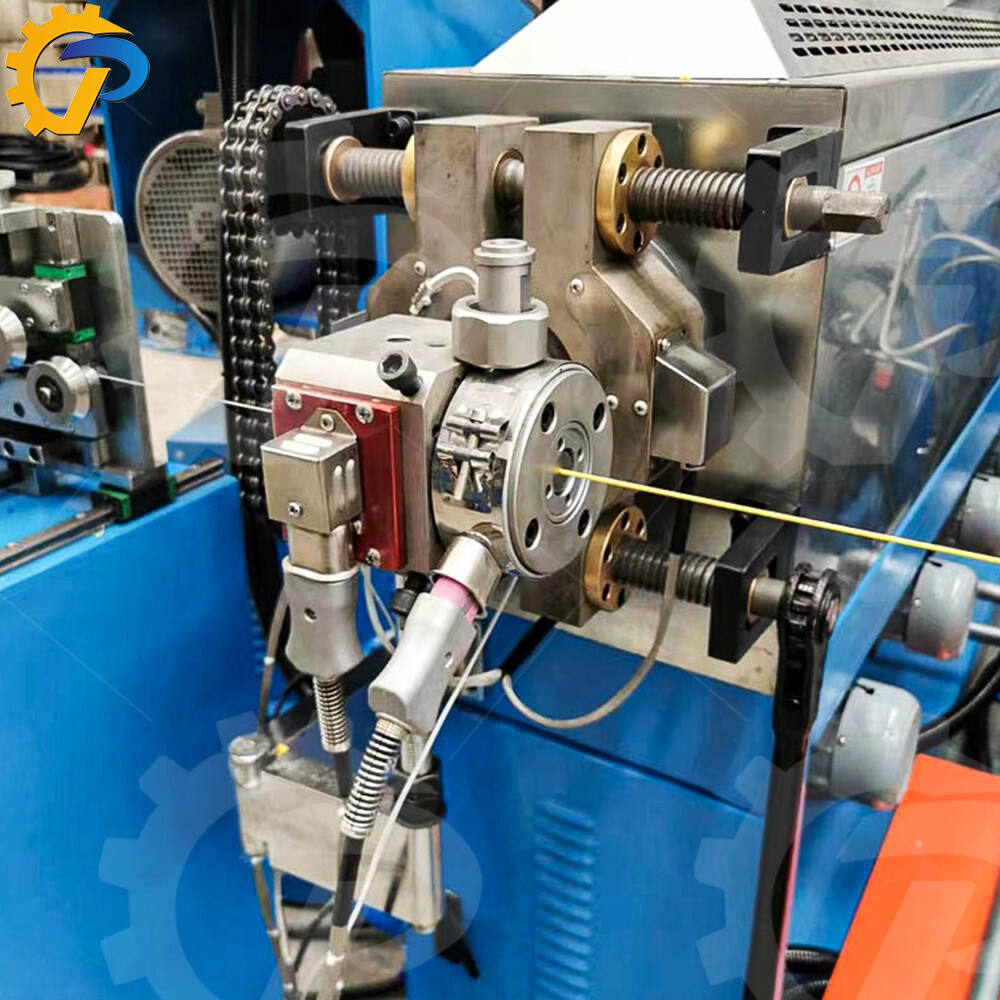

Cable Extrusion Machine

Cable Extrusion Machine

(18)50 cable extrusion machine

The 50 Cable Extrusion Machine is designed for high-precision extrusion of insulation and sheath layers for wires and cables, including USB wires. Supporting materials like PVC, XLPE, PE, and HFFR, this machine ensures consistent quality with customizable extruder sizes (SJ30-SJ150) and layer configurations (single, double, or triple-layer co-extrusion). Ideal for manufacturers seeking durable, flame-retardant, and high-performance cable production, this machine enhances efficiency and output reliability.

90 cable extrusion machine

The 90 Cable Extrusion Machine is a high-performance single-screw extruder designed for the insulation and sheathing of power cables, building wires, and communication cables. With a 90mm screw diameter and compatibility with materials like PVC, PE, XLPE, and LSZH, it offers efficient, high-speed production for large-scale cable manufacturing operations. Its intelligent PLC control system and automation features ensure consistent quality, safety, and reduced labor costs.

70+35 Cables Manufacturing Data Building Copper Electrical Wire Cable Making Machinery Extruder Extrusion Sheath Machine

The 70+35 Cable Extrusion Machine is a high-performance jacketing and sheathing extrusion line designed for manufacturing insulated and sheathed building cables. Ideal for PVC, PE, and XLPE materials, it supports double-color extrusion and two-wheel traction. With dual extruders (φ70mm and φ35mm), this machine ensures superior flexibility, high output, and reliable operation across a wide range of cable production needs in the electrical industry.

70+45 cable extrusion machine

The 70+45 Cable Extrusion Machine is a high-speed insulation and sheathing production line engineered for double-layer co-extrusion. Designed for processing PVC, XLPE, PE, and HFFR materials, this versatile machine is ideal for manufacturing high-quality building cables with excellent insulation and protective sheaths. With advanced extrusion technology and reliable output, it is an ideal solution for cable manufacturers seeking efficiency and consistency in large-scale cable production.

90+70 cable extrusion machine

The 90+70 Cable Extrusion Machine is a high-efficiency twin-screw extrusion line designed for the simultaneous extrusion of insulation and sheath layers. Built for use with PVC, PE, and XLPE materials, it supports the production of power cables, building wires, communication cables, and photovoltaic cables. Featuring advanced PLC control and a user-friendly interface, it ensures stable, automated operation and is ideal for medium and low voltage cable manufacturing.

70 cable extrusion machine

The 70 Cable Extrusion Machine is a high-speed, fully automated cable manufacturing solution engineered for precision and durability. Designed for the efficient extrusion of PVC, XLPE, PE, and HFFR materials, this production line is ideal for producing BV, BVR, BVV, and RV cable sheaths. With a robust build and advanced control systems, it delivers consistent performance and high productivity in modern cable-making operations.

100 cable extrusion machine

The 100 Cable Extrusion Machine is a robust single-screw extruder designed for high-efficiency production of cable insulation and sheath layers. With a 100 mm screw diameter, it handles PVC, PE, XLPE, LSZH, and other thermoplastic materials, making it ideal for medium/high-voltage power cables, communication cables, and photovoltaic cables. Featuring automated feeding, cooling, and wire collection, this machine ensures high output, precision, and reliability for industrial cable manufacturing.

60+35 cable extrusion machine

The 60+35 Cable Extrusion Machine is a high-performance, dual-layer extrusion system designed for precision and efficiency in wire and cable production. Combining a 60mm primary extruder with a 35mm secondary extruder, this machine ensures uniform material distribution, high output, and superior insulation/sheath quality. Ideal for PVC, XLPE, and flame-retardant polyolefin materials, it is perfect for large-scale manufacturing of durable, high-grade cables.

200 cable extrusion machine

The 200 Cable Extrusion Machine is engineered for high-volume production of large-size cables, offering superior insulation and sheathing for XLPE, PVC, PE, and HFFR materials. Equipped with a high-performance motor, precision temperature control, and durable screw-barrel system, it ensures fast extrusion speeds, stable output, and minimal material waste. Ideal for industrial-scale cable manufacturing, this machine delivers consistent quality, energy efficiency, and adaptability for diverse wire and cable applications.

Chipeng 90+40 High Precision PLC Control Rubber Wire Extrusion Production Line

This machine is suitable for covering the sheath layer of wires and cables by extruding CPE (chlorinated polyethylene) thermoplastic cable material through the hot extrusion method. This machine has the advantages of high temperature control accuracy, stable wire output performance, energy saving and stability, as well as a high degree of automation.

120+60 cable extrusion machine

The 120+60 Cable Extrusion Machine is a premium-grade production line designed for high-efficiency cable sheathing and insulation extrusion. Featuring a 25:1 L/D ratio screw and Siemens PLC control system, this machine delivers precision processing of XLPE, PVC, PE, and HFFR materials. Its robust construction with high-quality screw and barrel ensures long-term stability, while the energy-efficient design minimizes operational costs for industrial cable manufacturing.

60 cable extrusion machine

The 60 cable extrusion machine is a high-performance solution designed for the efficient extrusion of insulation and sheath layers on wires and cables. Engineered with PLC and touch screen control, it ensures smooth operation, minimal maintenance, and high-speed production. This machine is compatible with a wide range of materials, including PVC, XLPE, PE, and HFFR, making it ideal for modern cable manufacturing facilities.