Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

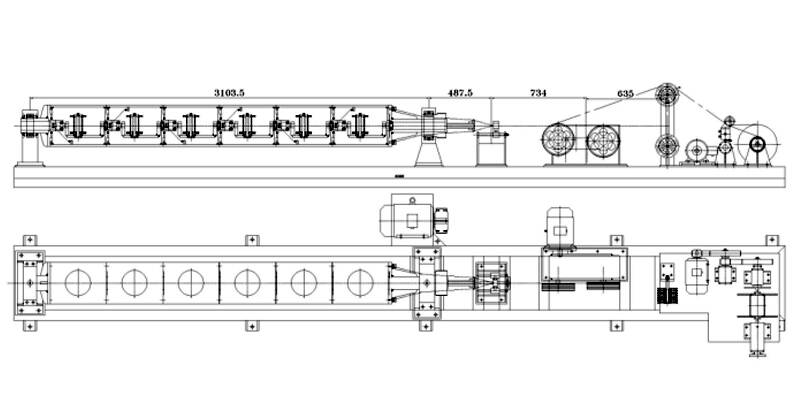

JGG300/12+1 Tubular Stranding machine

The JGG300/12+1 Tubular Stranding Machine is engineered for stranding bare copper wire, bare aluminum wire, and ACSR with high efficiency and precision. It integrates an advanced shaft-less design, direct motor drive, and pneumatic braking system to ensure smooth operation and excellent lay length control. This robust, user-friendly machine is ideal for cable manufacturers looking to optimize their wire processing capabilities.

Product Features

Shaft-less Bobbin Handling with Pneumatic Release

The machine's shaft-less structure features automatic mechanical clamping and pneumatic bobbin release, allowing for quick changeovers and enhanced operational convenience.

AC Variable Frequency Direct Drive System

Driven by an AC variable frequency motor connected through synchronous pulleys, the machine ensures stable torque output and energy-efficient, adjustable speed control.

Advanced Bearing Support Structure

The stranding cage is supported by durable bearings at both ends and a large center bearing, delivering reduced vibration, longer life, and smooth high-speed operation.

Pneumatic Brake for Precise Lay Length Control

Equipped with a pneumatic braking system, the machine offers reliable braking force and ensures synchronized speed reduction between stranding and traction, maintaining consistent lay length.

Mechanical Friction Tension Control System

The pay-off system uses a mechanical friction control mechanism for adjustable and stable wire tension, helping improve product uniformity during the stranding process.

Technical Specifications

Product Advantages

Stable and Consistent Wire Stranding

The pneumatic brake ensures stranding and traction speeds reduce together, maintaining uniform lay lengths and enhancing final product quality.

Quick and Easy Wire Threading

The wire threading path is designed along the outside of the stranding cage, making the threading process intuitive and time-saving for operators.

Strong Frame with Double Hinge Support

The machine’s full frame structure with front and back dual support improves structural stability, even during continuous high-speed operation.

Reliable and Simple Manual Locking System

The plug screw structure includes a manual locking feature, ensuring secure operation with minimal manual effort.

Flexible Application Range

Designed to strand various wire types, including bare copper, aluminum, and ACSR, the machine is adaptable to different manufacturing needs.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost