Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

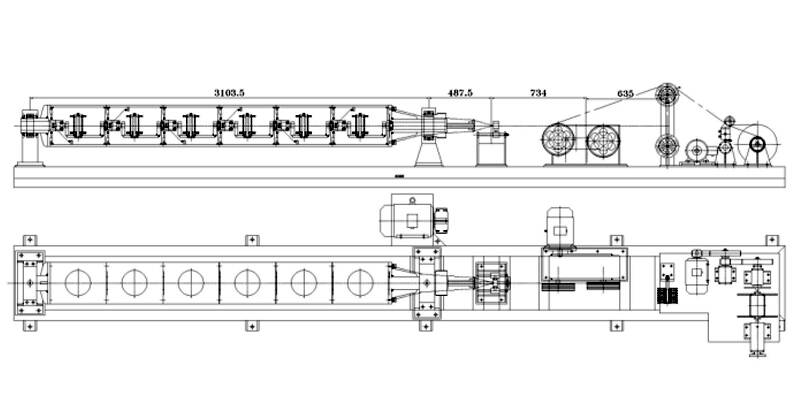

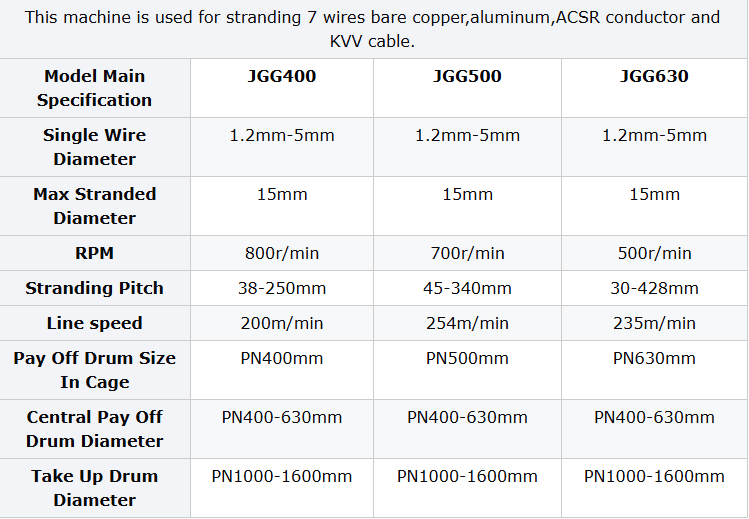

JGG500/12+1 Tubular Stranding machine

The JGG500/12+1 Tubular Stranding Machine is a high-performance solution for stranding bare copper, aluminum wire, and ACSR with enhanced precision and safety. Engineered with advanced control systems, wire protection mechanisms, and efficient lubrication, this machine ensures stable, high-speed operation while improving wire quality and minimizing downtime. It is ideal for manufacturers seeking a durable, efficient, and intelligent stranding solution for modern cable production.

Product Features

Intelligent Touch Screen Interface

Operators can easily monitor and adjust multiple parameters via the user-friendly touch screen, enabling efficient control and reducing the learning curve for new users.

Quick-Change Roller System

The roller design allows for fast and convenient replacement, significantly reducing downtime and improving productivity during maintenance or production changes.

Adjustable Compacting Force with Bolt Mechanism

The compacting force can be precisely controlled using bolts, providing better control over wire density and uniformity in the stranding process.

Single Wire Preforming Device

A built-in single wire preformer enhances the roundness and consistency of the finished wire, improving both aesthetics and functional quality.

Advanced Lubrication and Cooling System

The central bearing is lubricated and cooled by a thin oil circulation system, supported by an independent oil station, ensuring optimal performance under continuous operation.

Technical Specifications

Product Advantages

Superior Wire Quality

Preforming and compacting systems work together to improve the roundness, compactness, and appearance of stranded wires.

Reduced Downtime and Easy Maintenance

Quick-change rollers and intuitive controls streamline maintenance tasks, allowing more production time and less machine stoppage.

Enhanced Safety Features

Equipped with a centrifugal wire break protection system and interlocked sliding safety fence, the machine ensures high operator safety during operation.

Stable and Precise Lay Length Control

The pneumatic brake system ensures synchronous deceleration between the stranding cage and traction line, resulting in a consistent lay length.

Durable and Vibration-Free Operation

Supported by high-precision bearings at both ends and a large middle bearing, the machine offers stable performance with reduced mechanical wear.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost