Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

500/36+36 Steel wire armor rigid framed stranding machine

The 500/36+36 Steel Wire Armor Rigid Framed Stranding Machine is engineered for high-capacity production of large-section copper and aluminum conductors. This industrial-grade machine produces circular, fan-shaped, and tile-shaped conductors while offering integrated tape wrapping functionality. Featuring advanced pneumatic tension control, dual-bearing support system, and shaft-less bobbin handling, it ensures precision stranding operations for demanding cable manufacturing applications. The robust frame construction guarantees stability during high-speed production of armored cables.

Key Features

Multi-Shape Conductor Production

Capable of manufacturing circular, fan-shaped, and tile-shaped conductors with consistent quality, meeting diverse industry specifications and standards.

Integrated Tape Wrapping Function

Specialized design incorporates copper tape shielding and wrapping operations, eliminating the need for secondary processing in armored cable production.

Advanced Tension Control System

Pneumatic tension regulation with electronic feedback maintains constant wire tension throughout operation, from full bobbin to empty, ensuring uniform strand quality.

Dual-Bearing Support Structure

Heavy-duty stranding carriage supported by front and rear dual bearings provides exceptional stability and weight distribution for high-speed operation.

Shaft-Less Pneumatic Bobbin System

Innovative shaft-less design with pneumatic clamping and mechanical safety lock enables quick bobbin changes while maintaining operational safety standards.

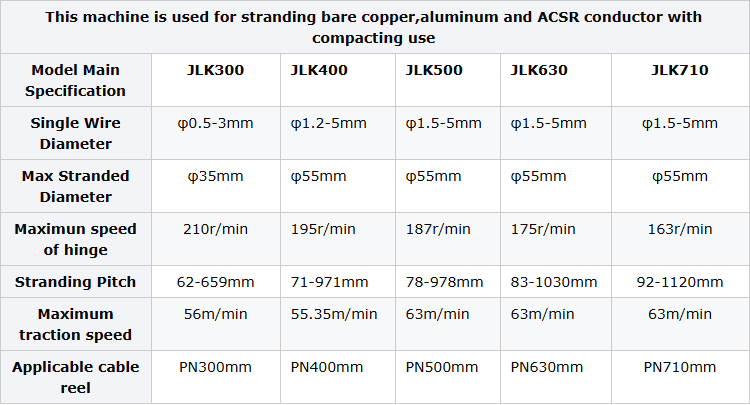

Technical Specifications

Product Advantages

High-Capacity Production - Designed for large-section conductors up to 36+36 configurations

Precision Engineering - Dual-bearing support ensures vibration-free operation at high speeds

Automated Tension Control - Maintains consistent strand quality throughout production runs

Versatile Functionality - Combines stranding and tape wrapping in single operation

Safety-Centric Design - Mechanical locks and fail-safe mechanisms protect operators

Reduced Downtime - Quick-change bobbin system maximizes production efficiency

Hanging Device:

What Shape Cable Can Be Made?