Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

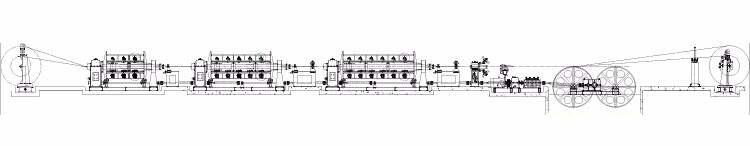

JLK500/24+24 Steel wire armor rigid framed stranding machine

The JLK500/24+24 Steel Wire Armor Rigid Framed Stranding Machine is designed for high-capacity cable manufacturing involving large cross-section copper and aluminum conductors. Engineered for precision and safety, it features advanced wire forming, compacting, and tension control systems. With robust structural integrity and automation capabilities, this equipment delivers superior performance for producing armored and shaped conductors in demanding industrial environments.

Product Features

Wire Preforming Device for Strand Integrity

Each stranding carriage is equipped with a preforming unit to prevent loosening of wire after the conductor section is disconnected, ensuring stable output.

Multifunctional Wire Merging and Compacting System

The machine integrates wire merging and round wire forming with a sector-shaped compacting mold for high-quality conductor shaping.

Advanced Gearbox Lubrication with Dedicated Drive

An individual motor-driven gear pump provides continuous lubrication to the gearbox, enhancing operational reliability and component lifespan.

Safety Electric Fence with Accessible Operator Entry

Each carriage includes an electric safety fence with a liftable door for secure, efficient, and operator-friendly loading and unloading.

Pneumatic Braking and Bobbin Handling System

Equipped with a pneumatic brake and overall side loading devices on each section for safer control and more efficient bobbin management.

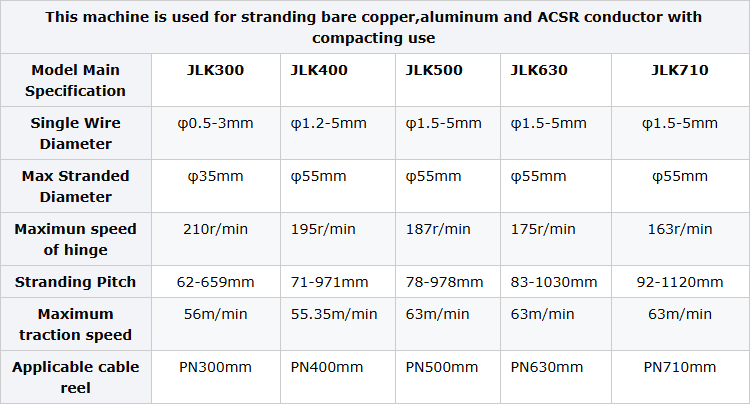

Technical Specifications

Product Advantages

Ensures Tight, Stable Wire Formation Post-Stranding

The preforming device maintains wire tension and structure even after the stranding process is completed.

Supports High-Volume, Large Cross-Section Cable Production

Ideal for industrial-scale production of copper and aluminum conductors with long length and wide cross-sections.

Minimizes Wear and Tear on Key Components

Continuous lubrication via motor-driven gear pump reduces mechanical stress and extends service life.

Streamlines Operator Workflow and Safety

Electric safety fences with entry doors improve accessibility while maintaining a safe work environment.

Reduces Downtime Through Quick Bobbin Handling

Side-loading devices on each carriage simplify bobbin replacement and significantly reduce auxiliary operation time.

Hanging Device:

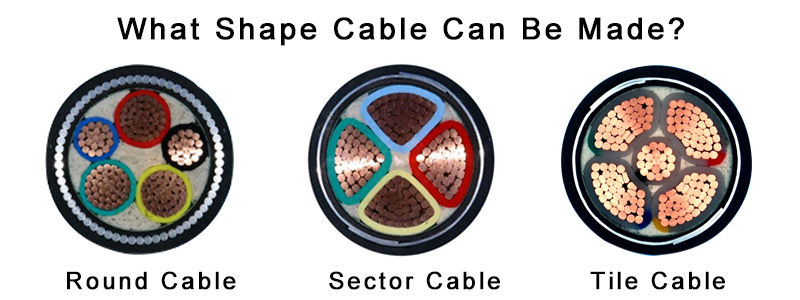

What Shape Cable Can Be Made?