Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

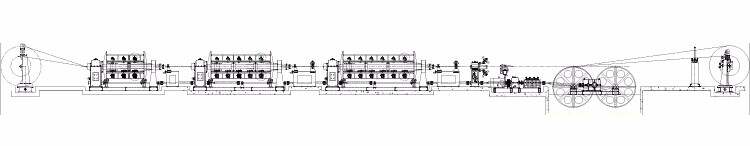

JLK500/6+12+18 rigid framed stranding machine

The JLK500/6+12+18 Rigid Framed Stranding Machine is a high-precision stranding solution designed for efficient production of compact and round wire conductors. Built with a durable frame structure, dual-bearing support, and advanced automation, it ensures stable operation, easy bobbin handling, and excellent wire forming performance. Ideal for large-scale manufacturing, this machine combines safety, reliability, and high output in a user-friendly design.

Product Features

Robust Frame with Dual-Bearing Support

The stranding carriage is supported by front and rear dual bearings, providing enhanced stability and smooth high-speed operation.

Integrated Wire Preforming and Compacting System

Each stranding carriage includes a wire preforming device and a sector-shaped compacting mold, preventing loosening and ensuring dense conductor structure.

Versatile Wire Merging and Forming Mold

Equipped with a dual-function mold for wire merging and forming circular cross-sections, offering flexibility for different cable designs.

Efficient Bobbin Handling System

Shaft-less pneumatic clamping and releasing mechanism combined with an overall side-loading device simplifies bobbin changes and reduces downtime.

Enhanced Operator Safety and Accessibility

Includes an electrically controlled lift door for operator access and a mechanical safety locking mechanism for secure operation during maintenance.

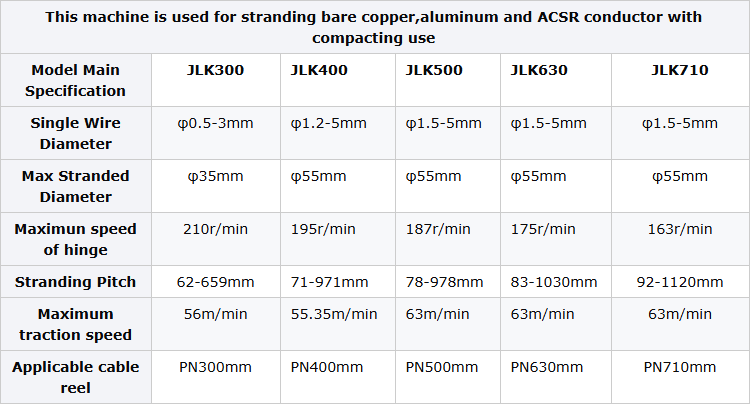

Technical Specifications

Product Advantages

Supports High-Speed, Stable Production

The dual-bearing frame structure ensures vibration-free, high-speed rotation for continuous, stable production.

Prevents Wire Loosening During Cutting

The wire preforming system maintains tight winding even after cutting, improving product quality and consistency.

Reduces Manual Labor and Setup Time

Pneumatic clamping and automatic side-loading bobbin devices significantly reduce auxiliary work and improve overall efficiency.

Adaptable Motor Configuration

Allows for either single or split motor configurations, providing flexibility based on production requirements.

User-Friendly and Safe Design

Electric fence doors and safety locks ensure easy access and protect operators during daily operation and maintenance.

Hanging Device:

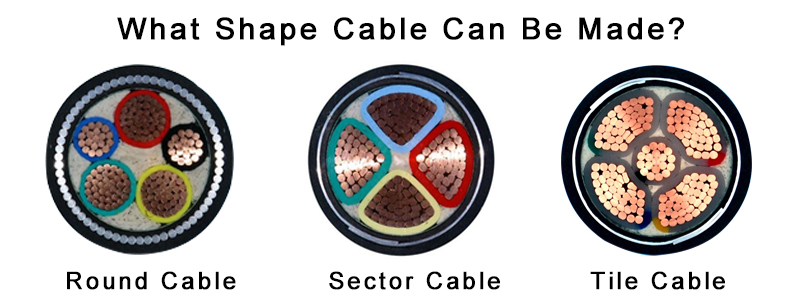

What Shape Cable Can Be Made?