Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

JLK630/42+42 Steel wire armor rigid framed stranding machine

The JLK630/42+42 Steel Wire Armor Rigid Framed Stranding Machine is engineered for high-efficiency production of large-length, large-cross-section copper and aluminum core stranded cables. Featuring pneumatic tension control, ground axis linkage, and PLC automation, this machine ensures precision, stability, and high-speed performance. It supports round, fan-shaped, and tile-shaped irregular conductors, making it ideal for industrial cable manufacturing. With advanced electronic control and easy operation, it maximizes productivity while maintaining consistent quality.

Product Features

Pneumatic Tension Control for Stable Stranding

Equipped with automatic tension adjustment, the machine maintains consistent wire tension from full to empty bobbins, ensuring uniform strand quality without manual intervention.

Ground Axis Linkage for Precise Pitch Control

The ground axis linkage system guarantees stable and accurate twisted wire pitch, while the rigid frame structure enhances durability for high-speed operation.

PLC & Touch Screen Automation

A programmable controller (PLC) and touch screen interface allow easy setup, real-time monitoring, and adjustment of process parameters, improving efficiency and reducing errors.

Integral Upper & Lower Wire Tray with Pneumatic Clamping

The pneumatic clamping system enables quick bobbin changes, reducing auxiliary time and boosting production efficiency.

Reliable Safety & Break Protection

Each bobbin features mechanical break protection and electrical switch detection, ensuring safe, interruption-free operation for continuous production.

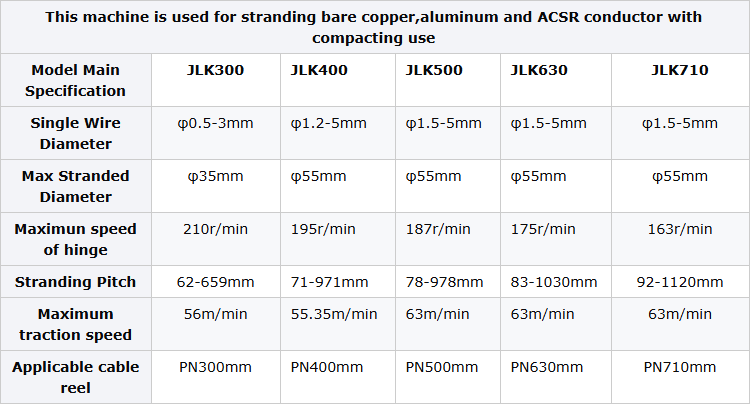

Technical Specifications

Product Advantages

High-Speed Performance – Rigid frame and optimized mechanics allow for faster stranding without compromising precision.

Automated Operation – PLC and touch screen control minimize manual adjustments, enhancing workflow efficiency.

Consistent Tension Control – Pneumatic and electronic tension systems maintain uniformity across all production stages.

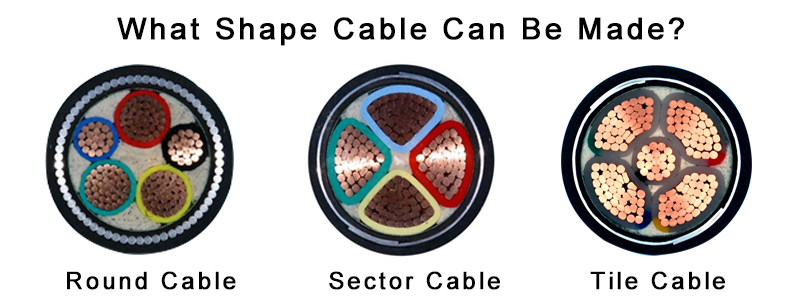

Versatile Conductor Production – Supports round, fan-shaped, and tile-shaped conductors for diverse cable applications.

Durable & Low-Maintenance – Robust construction and individual motor-driven lubrication extend machine lifespan.

Hanging Device:

What Shape Cable Can Be Made?