Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

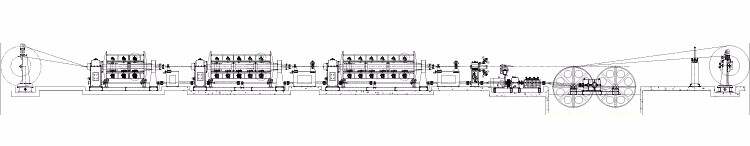

JLK630/6+12+18 rigid framed stranding machine

The JLK630/6+12+18 rigid framed stranding machine is specifically designed for producing high-quality stranded conductors, including copper, aluminum, and ACSR. Supporting up to 37 wires with a cross-section range of 10–185mm², this machine ensures stable tension control, precision stranding, and compacting capabilities. It is ideal for manufacturing circular, fan-shaped, and tile-shaped conductor profiles in large-scale cable production environments.

Product Features

Stable Wire Tension Control with Pneumatic System

The machine features a pneumatically controlled wire tension system that maintains consistent tension from full to empty bobbins, using electronic detection and a proportional control valve for real-time adjustment.

Shaft-less Pneumatic Bobbin Clamping System

Equipped with a shaft-less pneumatic clamping and releasing mechanism, along with a mechanical safety lock, this system simplifies bobbin handling while improving operator safety and loading efficiency.

Programmable Control with Touch Screen Interface

An integrated PLC and touch screen control system provides centralized monitoring and control of all machine functions, enabling precise adjustment of process parameters and ensuring consistent production results.

Advanced Brake and Drive Technology

The machine is powered by split motors and features a pneumatic braking system, offering smooth startup, stable operation, and controlled stopping—crucial for protecting wires during high-speed stranding.

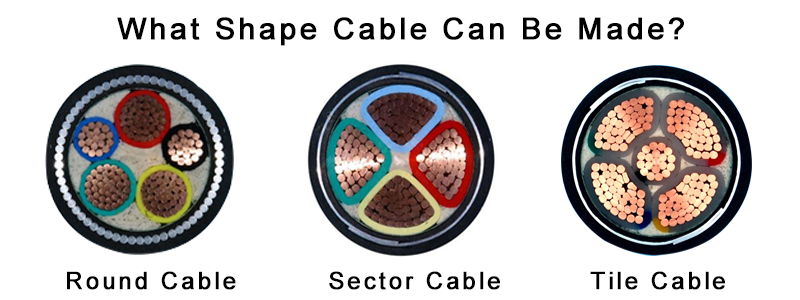

Versatile Conductor Shaping Capability

This machine supports the production of circular, fan-shaped, and tile-shaped conductors, making it a flexible solution for manufacturers working with a variety of cable designs and compacted conductors.

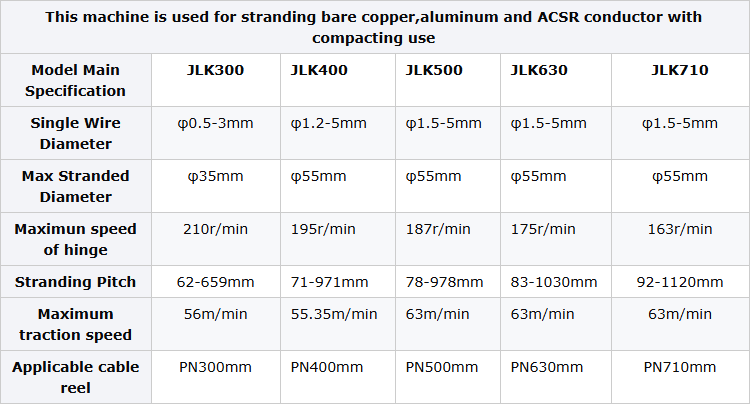

Technical Specifications

Product Advantages

Ideal for High-Volume Production: With support for 37 wires and cross-sections up to 185mm², it is built for industrial-scale output.

Reliable and Consistent Tension Control: Pneumatic tension regulation ensures wire integrity and minimizes production defects.

Safe and Efficient Operation: Integrated safety electric fences and automatic systems reduce risks and downtime during bobbin changes.

Multi-Material Compatibility: Supports copper, aluminum, and ACSR conductors, making it adaptable to a wide range of applications.

Easy to Operate and Maintain: The user-friendly interface and modular mechanical design streamline both operation and maintenance.

Hanging Device:

What Shape Cable Can Be Made?