Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

JLK630/6+12 rigid framed stranding machine

The JLK630/6+12 rigid framed stranding machine is built for high-precision stranding of up to 19 wires with cross-sections from 10–70mm². Ideal for copper and aluminum conductors, it features split motor drive, automatic tension control, and wire preforming to ensure structural integrity of finished conductors. Designed for efficient and reliable production, it supports both round and sector-shaped wire compacting for diverse cable applications.

Product Features

Rigid Frame Design with Dual-Bearing Support

The stranding carriage is supported by front and rear dual bearings, ensuring long-term mechanical stability and precise wire positioning even during high-speed operation.

Wire Preforming Device for Structure Retention

Each carriage includes a wire preforming device to maintain conductor structure, preventing loosening or deformation after cutting or during handling.

Automatic Pneumatic Tension Control System

The machine uses pneumatic control with proportional valves and electronic sensors to automatically maintain consistent wire tension from full to empty bobbins.

Integrated Upper and Lower Bobbin Tray Design

The integral upper and lower bobbin tray system with pneumatic clamping simplifies bobbin changes, reduces auxiliary time, and improves overall line productivity.

Accurate Wire Monitoring and Break Protection

Equipped with mechanical contact monitoring and electrical switch detection, each bobbin features automatic wire break protection to ensure production safety and reduce material waste.

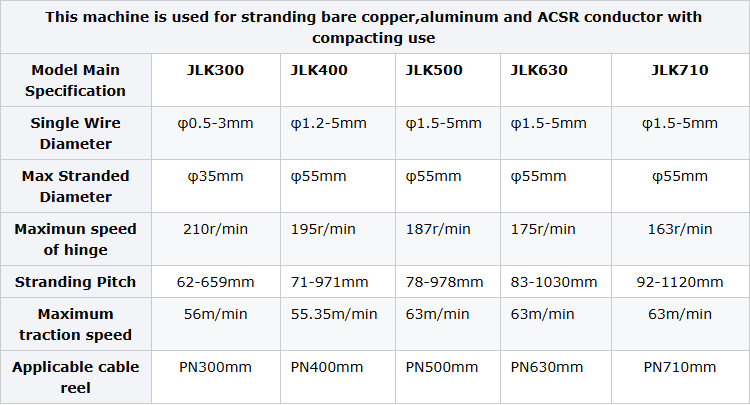

Technical Specifications

Product Advantages

Consistent and Stable Tension: Automatic adjustment ensures stable stranding tension regardless of bobbin fill level.

Time-Saving Operation: The integrated bobbin system and pneumatic clamping speed up setup and reduce downtime.

High Structural Integrity of Conductors: Preforming devices ensure that wires stay compact and maintain shape post-stranding.

Precision Control: Each bobbin is monitored with reliable switch detection for real-time break alerts and quick response.

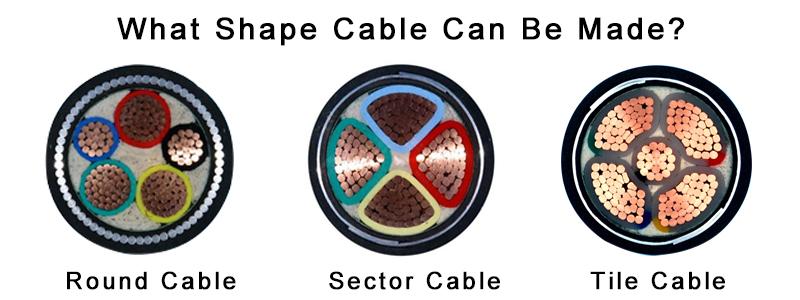

Versatile Cable Output: Supports both round and sector-shaped compacted conductors for a variety of cable product lines.

Hanging Device:

What Shape Cable Can Be Made?